Description

- Origin: Mainland China

- Certification: CE

Photodiode is one of the most commonly used sensors in many optical measurements。Such as absorption and emission spectra、Color measurement、Turbidity、Applications such as gas detection all depend on photodiodes to realize precise optical measurement。The photodiode produces a current proportional to the amount of light that strikes the active area。Transimpedance amplifiers are required for most measurement applications,To convert photodiode current to output voltage。chart1Schematic diagram of display circuit。

chart1 Simple transimpedance amplifier circuit

The photodiode of this circuit operates in photovoltaic mode,The operational amplifier keeps the voltage on the photodiode at0 V。This is the most common configuration in precision applications。The voltage current curve of photodiodes is very similar to that of conventional diodes,However, the whole curve of the former will move up or down as the light level changes。chart2aDisplay typical photodiode transfer function。chart2bIs the enlarged graph of the transfer function,Indicates that even in the absence of light,The photodiode also outputs a small amount of current。This dark current will rise as the reverse voltage on the photodiode increases。Most manufacturers operate at a reverse voltage of10 mVThe dark current of photodiode is given under the premise of。

chart2 Typical photodiode transfer function

After the light irradiates the active area of the photodiode,Current flows from cathode to anode。Ideally,All photodiode currents flow through the figure1Feedback resistance in,Generates a feedback voltage equal to the photodiode current times the feedback resistance。The circuit is simple in principle,But there are some challenges that must be solved if the system is to have the best performance。

DC considerations

The first challenge is to choose an operational amplifier with DC specifications that match the application requirements。For most applications,Low input offset voltage is the most important specification。Input offset voltage at amplifier output,This offset voltage increases the total system error;In the photodiode amplifier,It also produces other errors。Input offset voltage on photodiode,Generate more dark current,Further increase the system offset error。Calibration by software、AC coupling——Or both——Eliminate initial DC offset,However, large misalignment error will reduce the dynamic range of the system。Fortunately,,Input offset voltage in hundredsmVEven dozensmVWithin the scope of,There are a large number of operational amplifiers to choose from。The second important DC specification is the input leakage current of the operational amplifier。Current enters op amp input,Or enter anywhere except the feedback resistance,Will cause measurement error。Operational amplifiers with zero input bias current do not exist,But someCMOSorJFETThe input op amp is very close to this value。FETThe input bias current of the input amplifier increases exponentially with temperature。Many op amps provide85°Cor125°CSpecifications under;But if not provided,Then a better approximation isEvery ten degrees of temperature rise,The current doubles。

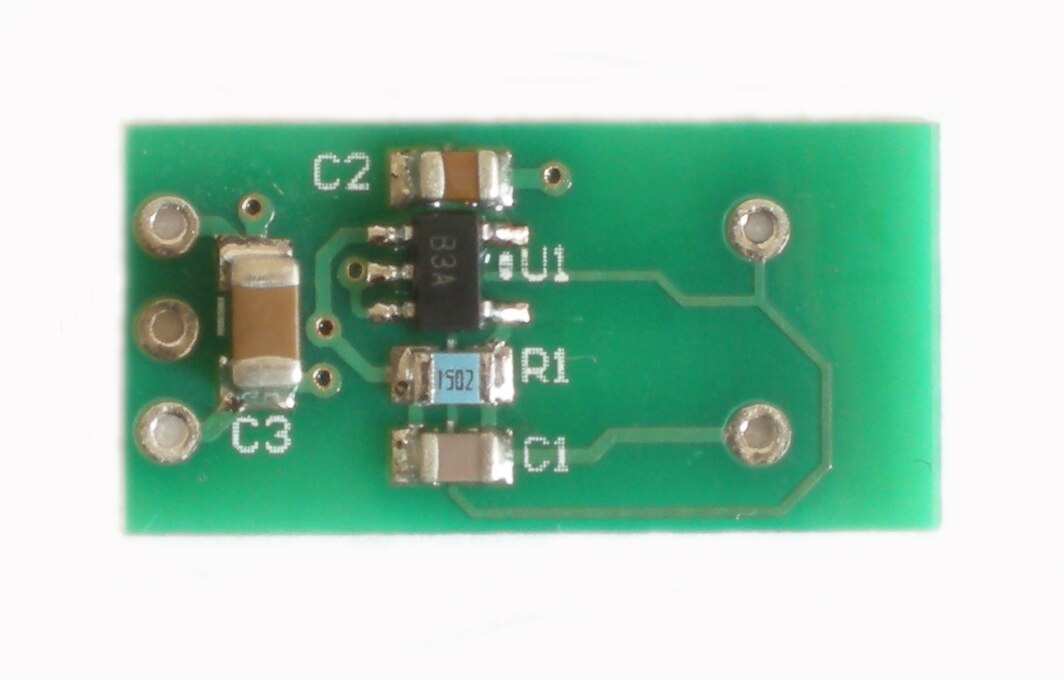

Another challenge is designing circuits and laying them out,This minimizes the external leakage current path——Leakage current will affect the performance of low input bias current operational amplifier。The most common external leakage current path is the printed circuit board itself。for example,chart3Display diagram1A feasible layout of photodiode amplifier in。Pink line representation+5 VPower rail,Supply power to the amplifier and transmit power to the rest of the circuit board。If in+5 VThe resistance between the wiring and the wiring carrying the photodiode current is equal to5 G(chart3ZhongyiRLexpress),that1 nACurrent will flow from+5 VRouting into amplifier。obviously,This is different from careful selection in application1 pAOp amp target violation。One way to minimize the external leakage current path is to increase the resistance between the path carrying the photodiode current and any other path。This may be as convenient as adding a large routing exclusion zone around the route to increase the distance from other routes。In some extreme applications,Some engineers will cancel it togetherPCBRouting,Expose the photodiode lead to air and connect it directly to the input pin of the operational amplifier。

chart3 Photodiode layout with leakage current path

Another method to prevent external leakage current is to lay a protection cable next to the cable carrying the photodiode current,And ensure that both routes are driven to the same voltage。chart4Display the protection routing around the network carrying the photodiode current。+5 VThe leakage current generated by wiring is then passedRLInflow protection routing,Instead of flowing into the amplifier。In this circuit,The voltage difference between the protection line and the input line is only related to the input offset voltage of the operational amplifier——This is another reason why we choose low input offset voltage amplifier。

chart4 Using protective wiring to reduce external leakage current

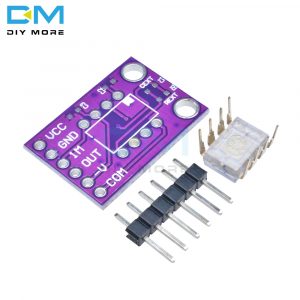

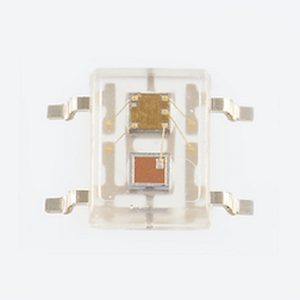

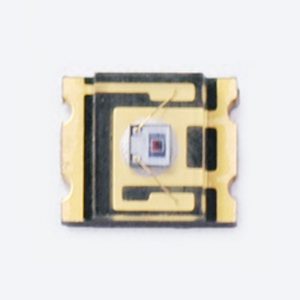

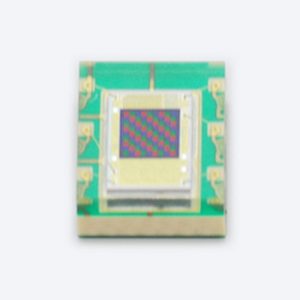

New 50pcs SGPD638B PD638B The wavelength of infrared receiving tube is 940 nm in stock

New 50pcs SGPD638B PD638B The wavelength of infrared receiving tube is 940 nm in stock

Reviews

There are no reviews yet.